Description

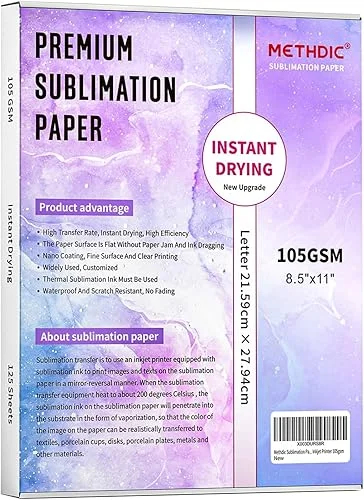

Does Thicker Paper Mean Better Usability? No, The Use Effect Of Sublimation Paper Mainly Affects The Ink Absorbing Layer On The Surface. On The Contrary, The Paper Is Thinner And Will Not Experience Ink Jamming. The Printing Is Very Smooth, And The Transfer Effect Is Also Very Good. The Vast Majority Of Industrial Printing Machines Use Thinner Materials, Using 40 GsmSublimation Transfer Is To Use An Inkjet Printer Equipped With Sublimation Ink To Print Images And Texts On The Sublimation Paper In A Mirror-Reversal Manner. When The Sublimation Transfer Equipment Heat To About 200 Degrees Celsius , The Sublimation Ink On The Sublimation Paper Will Penetrate Into The Substrate In The Form Of Vaporization, So That The Color Of The Image On The Paper Can Be Realistically Transferred To Textiles, Porcelain Cups, Disks, Porcelain Plates, Metals And Other Materials. Sublimation Uses Special Paper Named Sublimation Paper, Ink And Polyester-Coated Items That All React With Each Other. When Heated To High Temperatures, Sublimation Ink Turns Into A Gas And The Pores Of The Polyester Coated Item Open Up Allowing The Gas To Enter. Then, Once Removed From The Heat The Pores Of The Polyester Item Close Up Trapping The Ink Inside Of The Item. Sublimation Items Are Smooth To The Touch. You Won’T Be Able To Feel Any Image Outline If You Run Your Fingers Across The Sublimated Item. Items You Will Need White or light color polyester fabric garment or sublimation blanks.For best results, use fabric with tight weave. Heat Press Parchment paper or a Teflon Sheet Sublimation Transfer PaperBe Sure To Mirror Or Flip Your Image Prior To Printing. Be Sure To Print On The Bright White Side Of The Paper. Be Sure To Use Sublimation Ink And Sublimation Transfer Paper.Sublimation Transfer Ink Must Be Used. Good-Quality Sublimation Ink Should Not Clog The Nozzles, With Vivid Colors And Good Stability. Adjust The Color Density In The Computer To Avoid Excessive Ink That Is Not Easy To Dry. After Adjustment, You Need To Check The Effect Of Thermal Transfer. Adjust The Appropriate Hot Pressing Temperature And Time. The Temperature Range Of Thermal Transfer Is About 180-230 Degrees Celsius, And The Time Is About 10-30 Seconds. A Small Test Should Be Done To Determine The Best Process Parameters Before The Formal Batch Transfer. The Hot Pressing Surface, Transfer Paper, And Substrate Surface Must Be Tightly Attached To Each Other During Sublimation Transfer. There Can Be No Gaps Between Them, Otherwise The Transfer Image And Text Will Be Blurred.

High Transfer Rate, Instant Drying, High Efficiencyuff0cSmooth printing, no paper or ink jam The Paper Surface Is Flat Without Paper Jam And Ink Dragging Nano Coating, Fine Surface And Clear Printing Widely Used, Customized Thermal Sublimation Ink Must Be Used Waterproof And Scratch Resistant, No Fading 105g Paper Has A Good Transfer Effect Compared To 125g Paper, With Smooth Printing, No Paper Jamming, And No Ink Stains On The Edges And Corners

Reviews

There are no reviews yet.